- Home

-

About Us

- Products

- R&D Innovation,

- Sustainable Development

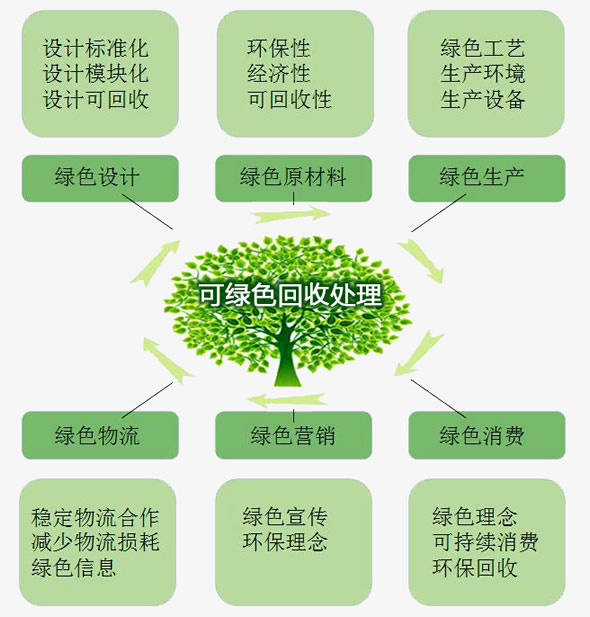

Green Supply Chain

The green supply chain, also known as the environmental supply chain or the environmentally conscious supply chain, refers to the operation mode of “no waste and no pollution”, “no any bad components” and “no side effects” in the entire supply chain. Green supply chain management considers the resource effects and environmental impacts of each link of the supply chain from the sustainable development of society and enterprises. It involves suppliers, production plants, distributors and users. The purpose is to obtain products from materials and processing. In the whole process of packaging, warehousing, transportation, use and end-of-life treatment, the impact on the environment (negative effect) is the smallest and the resource efficiency is the highest, so as to promote the coordinated development of economy and environment.

With the society's emphasis on the environment and people's awareness of environmental protection, green consumption has moved from fashion consumption to popularization, becoming the basic standard of people's consumption. Zhejiang Changfeng New Material Co., Ltd., as a rare all-water PU manufacturer in the industry, adheres to the concept of sustainable development and implements green supply chain management for lower-level raw material suppliers on the premise of ensuring its own green production. Provide a strength for the development of the green supply chain and enhance the company's market competitiveness. Fufeng New Materials has completed an assessment of existing suppliers, such as environmental issues in the supplier's production process, toxic waste pollution, hazardous gas emissions, etc., and has developed a regular audit plan. For potential suppliers, keep a backup in time to prevent potential risks.

- Products